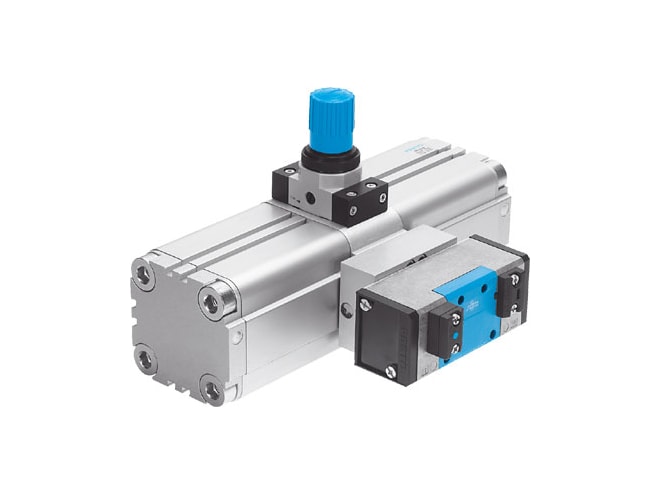

Festo DPA Series Pressure Booster

Compact, double-piston pressure intensifier with optional position sensing and air reservoir.

Overview

Features

- 40 to 100mm piston

- 10bar, 16bar, or double input outlet pressure

- Any mounting position

- Short filling times

- Long service life

- Operating medium:

- Compressed air as per ISO 8573-1:2010 [7:3:4]

- Position sensing for proximity sensor available

- Pressure booster/air pressure reservoir version available

- 2 to 20L air reservoir volume with combo option

- RoHS-compliant and conforms to VDMA24364-B1/B2-L

Description

The Festo DPA Series Pressure Booster has been designed to increase the pressure in air supply lines and, with its two coupled pressure chambers, it functions as a double-piston compressor. The DPA pressure booster has a pressure ratio of 1:2 for outlet pressures up to 16 bar. Optional features include double input pressure, position sensing for proximity sensors, and the option of an air pressure reservoir combination unit. Versions with an air reservoir have a capacity of 2 to 20 liters and can bypass the check valve to allow for constant filling of the air reservoir within the system.

No external energy other than compressed air is required to operate the DPA. The pressure booster starts up automatically when the input pressure is applied and the desired output pressure has not yet been reached. When the set output pressure is reached, the pressure booster stops operating to save energy, but restarts automatically when the output pressure drops again. The version of the DPA with proximity sensing provides an option of sensing individual strokes of the drive piston with the help of an external sensor or an adding counter.

When the DPA is pressurized with compressed air, integrated check valves automatically ensure the pressure on the secondary side is built up. The output pressure can increase to up to twice the value of the input pressure. The required output pressure is set using a manually operated pressure regulator. In the case of pressure boosters without a pressure regulator, the output pressure is always double the input pressure. The air supply to both drive pistons is controlled by a pneumatic directional control valve that reverses automatically when the stroke end position has been reached.

Need Help? Call an engineer at 1-802-880-3123

We're open 8:00 am to 5:00 pm ET